Energy & hold blanching

Jarwo BV has developped the revolutionary energy & hold blanching process using only steam. This process has got great advantages when compared to other methods.

With blanching the energy penetration to the center of any product is a function of temperature and time. The shorter the duration in the heat medium, the better the retention of color, solids and nutrients as the leaching action is reduced accordingly.

Steam blanchers and hot water blanchers keep the product in the heat medium until the desired center core temperature is reached. This is not an efficient process because it will overcook the outer surface of the product. The process ignores the factor time during heat penetration.

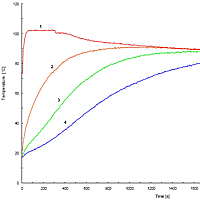

The curve shows an example of the heat penetration in a potato. The energy & hold blancher only exposes the product to steam for 4.5 minutes in the energy section followed by 35 minutes in the hold section to achieve a center core temperature of approximately

The same process principle applies to kernel corn, vegetables and fruit. It reflects in substantial steam savings with a corresponding reduction in effluent.

The energy & hold process only supplies steam to the surface of the product in the energy section. In the hold section the surface heat is allowed to equilibrate throughout the product. The center core temperature raises up to the desired level without the addition of any more steam. The short exposure time to heat leads to noticeable improvement in color, solids and nutrient rentention, particulary when compared to hot water blanchers.

- The advantages of energy & hold blanching, compared to steam or hot water blanching, are as follows:

- Reduction in effluent

- Lower steam consumption

- Less cooling costs

- Better color retention

- No nutrient losses

- No overcooking of product

- No water consumption